At Future Then we work closely with our customers to find the best solutions to solve their machine vision problems. We offer everything from quality inspection and identification, to solving difficult machine vision tasks in demanding and unpredictable environments. Thanks to 2D and 3D cameras and various types of sensors like laser scanners or similar, we will always find a solution to your problem.

Why do i need machine vision?

Errors in production and bad product quality can sometimes lead to costly recalls, waste and dissatisfied customers. The cost of such incidents can be large, especially if it is not detected early.

Manual inspection is not always easy and is prone to human error. In order to combat this you need machine vision solutions that can operate on its own and tackle any type of production environments.

Quality and Control

Making sure all products have the correct markings, the correct dimensions and meets quality requirements requires sensors that can read codes and measure the exact sizes of your product. In such applications we can provide you with systems for:

- Reading and control of text via OCR/OCV solutions

- Reading and control of 1D and 2D codes such as barcodes and QR Codes.

- Detecting defects or variations in different products or materials

- Detecting defects in different packaging

- Measuring and checking dimensions

Recognition

Whether you want a robot or machine to detect parts for pick and place operations or you want to recognize possible errors or machine failures before they happen, then our recognition solutions is for you. Some examples that we deliver:

- Detecting and distinguishing parts from one another

- Counting parts via images or video feed

- Early detection of ques and stuck products in machinery or pipes

- Early detection of machine failure with the help of camera or vibration sensor combined with machine learning.

Custom Solution for Tough Problems

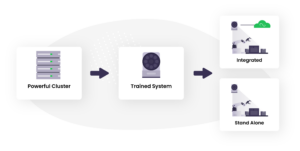

Where standard solutions fail we can leverage the power of AI with machine learning and create systems that can help solve your problems in unpredictable environments.

In such cases we analyze and gather data from the task and design a vision solution tailored to meet your demand with industrial precision and quality. With carefully picked hardware and machine learning models developed and trained on our powerful data-cluster, the possibilities become endless. The final solution can be setup as a stand alone turn key solution or connected to other systems like ERP, MES, SCADA or our own Future Then Vision software.

Integration with Future Then Vision

Our Future Then Machine Vision Software can be used to control and handle recipe management of one or multiple cameras or sensors. It can also be connected to your ERP, MES or SCADA systems for sending and receiving vital data from and to the production.

Future Then Vision can run on your own servers or be delivered as a turn key solution adapted to your environment.